This fall, we spent a week in Louisville, Colorado at Rupes BigFoot Polishing and three days in Chicago, Illinois at Dr. Beasley’s / Simon’s Shop to advance our knowledge and skills from the manufacturer’s who make the equipment and products we use in our shop on a daily basis.

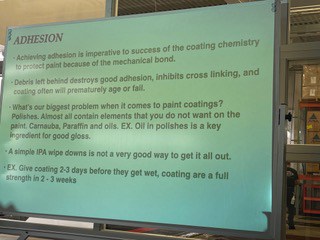

You may recall during your consultation visit or upon delivery conversations about proper contamination removal, washing and preparing surfaces for protection with ease of maintenance… “an analogy I commonly use is preparing and finishing a home for painting or woodworking, the surfaces must be very clean, and the chemistry of the products used must align for optimal results.”

Optimal performance is achieved when a surface is absolutely cleaned with quality products, adherence to application procedures, and keeping the chemistry aligned for a complete bond to all surfaces to be protected against contamination and ease of maintenance for you.

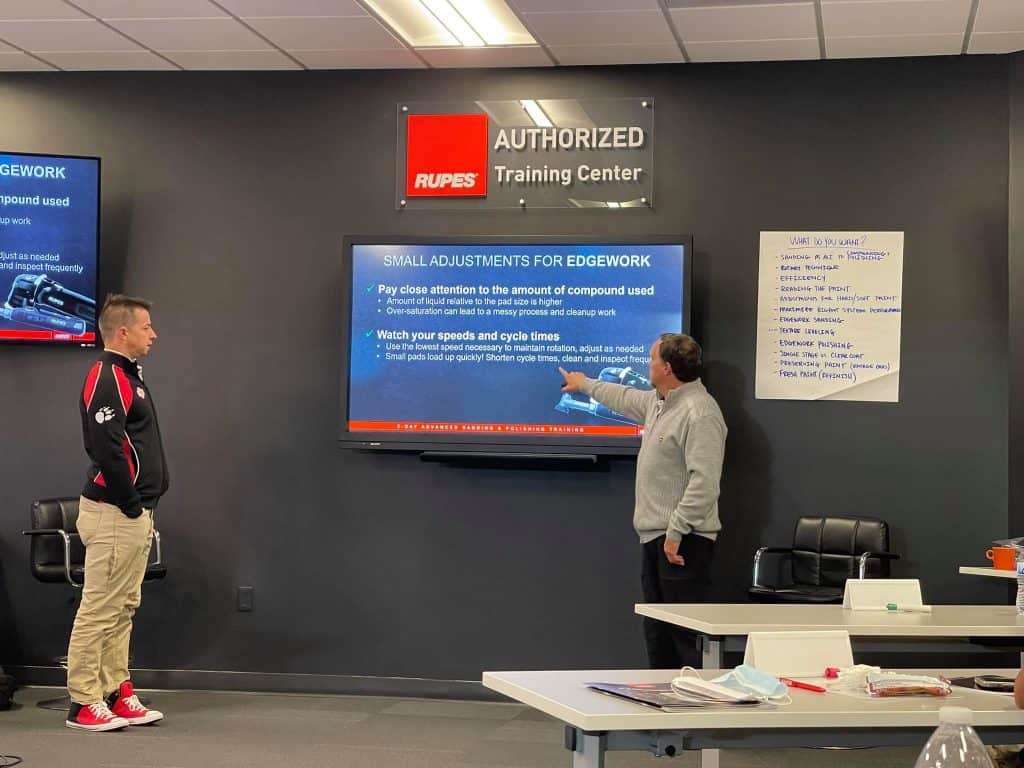

Utilizing polishing machines for maximum cut and shine is critical for a professional detailer. The Rupes training and development team led by Jason Rose unlocked some of the secrets behind the machines and their interaction with the painted surfaces when combined with various pads, products, and techniques.

Rupes training week also provided me with additional knowledge with a private instructor-based training session with Jason to add to the development of No Buff Too Tuff (NBTT) Detailing Academy.

Today, another breakthrough for better protection has arrived with nano surface primer polishing compounds and ceramic coatings with no VOCs invented by Jim Lafeber at Dr. Beasly’s and Simon’s Shop in Chicago.

For several years, advances in paint clear coat and paint protection and ceramic coatings have all been made from inorganic materials; however, polishes have not advanced enough to provide the correct chemistry link. Polishing compounds are all made from organic and inorganic materials combined. Organic materials must be removed with industrial-strength alcohol to remove the organic materials, creating tension in the painted surfaces to be protected.

To solve polishing compound compatibility issues, Dr. Beasley’s invented and released NSP’s nano surface primers that are made of all inorganic materials to solve the adhesion issues related to ceramic coating failures.

NSP’s leave a priming base and provide a ready surface, especially for ceramic coatings or any protection you want to apply. Compatibility provides a more durable, long-lasting finish without the worry from ceramic coating failure due to antiquated polishing compound issues related to the incompatibility of organic material left behind, creating surface tension that can lead to less than expected results.

Connecting with detailing industry leaders and inventors is another part of our commitment to always provide you with industry-leading detailing results.

Better Bond Better Shine to Last a Long Time!

Love Your Ride? Let us Love You back! Forever You will Shine!

FYWS! Happy Motoring,

Joe